|

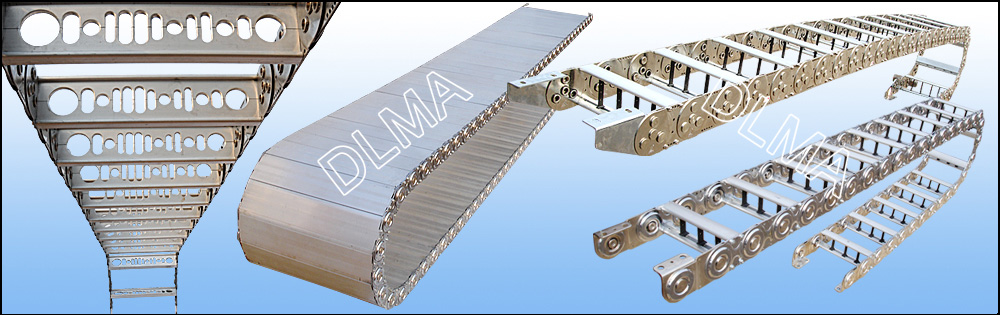

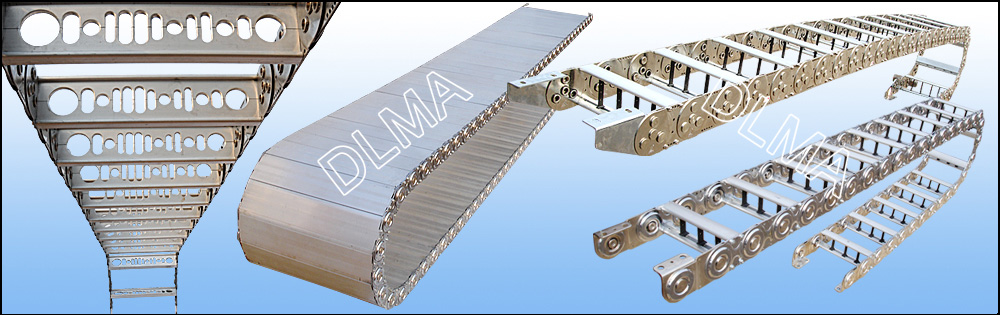

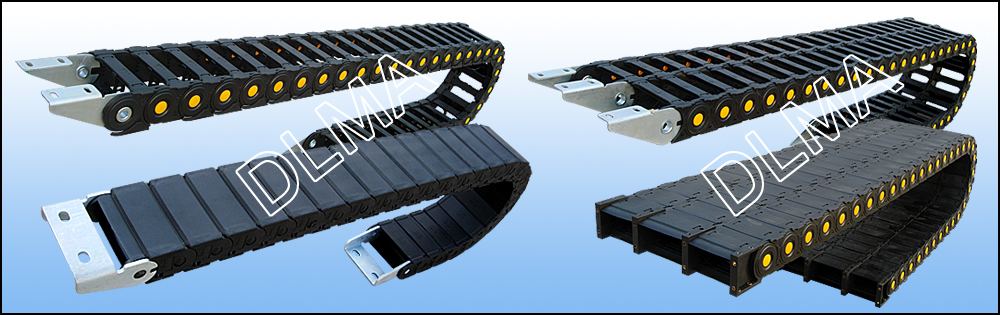

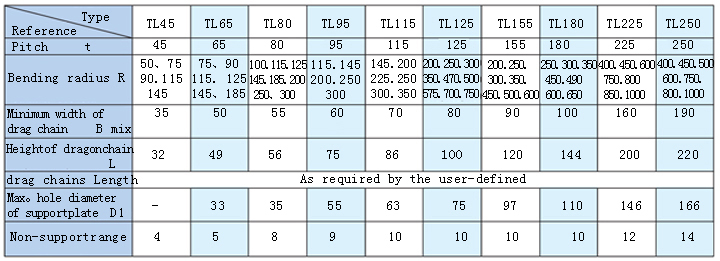

TL Type Steel drag chains main parameters of

Click the appropriate model type to enter a specific description

1.Drag chains are produced by using ItaIian technoIogy .

2.When non-standard bend radius or non-standa drag chains are reuired,we can make them according to the user's requlrements.

3.When the max. width Bmax is exceeded , compound type drag chains that consist of 3 chain crawlers can be used. See figure below.

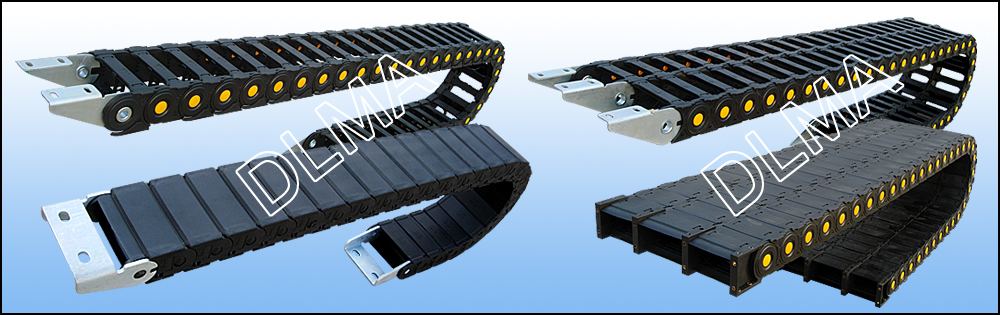

Selection of Drag Chains

1.The hole diameter of the inner cavity of supporting beard D1=d+≈0.1d(take round number).where,d= outslde diameter of cables,wires,liquid/gas hoses.

2.Thehe height of the supporting boardand the model number TLXX of drag chains depends on the the max.hole diameter of the inner cavlty of the supporting.

3.The bend radius depends on thefunctions of the drag chains.

(1).When there is a large load from larger caIibre or cables on the drag chains, high strength model I supperting board (integral) should be used

(2).When the size of the connectores are greater than that of the hole diameter of the inner cavity of supporting board or frequent assembly or dismantal operatlonS are required , type Ⅲ Supporting board ( frame type ) Can be used .

4. The width of supporting board B , can be decided according to the quantity of the cables installed so that the width of the drag chain B can be arrived.

5.When limitedby locatIons or environment and if bracing beard with Steel straps are needed , please contact our company for solutions.

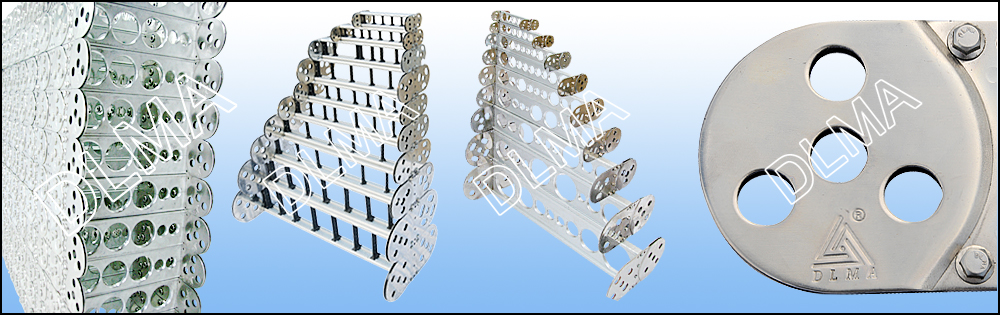

Drag chains with 3 chain board

one or more drag chain boards can be installed on a wider drag chain , because the max. length of the supporting board is 600mm 一650mm .This arrangement can also improve the stability of the narrower chains. In this way the conduit and the cables can be separated from one another by a third chain board。

Nofe : Parameters D,12,e be used for GLE type and f,j,k for TL type

E Iastic status for hydraulic pipes

Notet that the pressure of a hydraulic pipe may extend or contract downward . so the elasticity should be taken into consideration . especlally under high pressure or with long length.

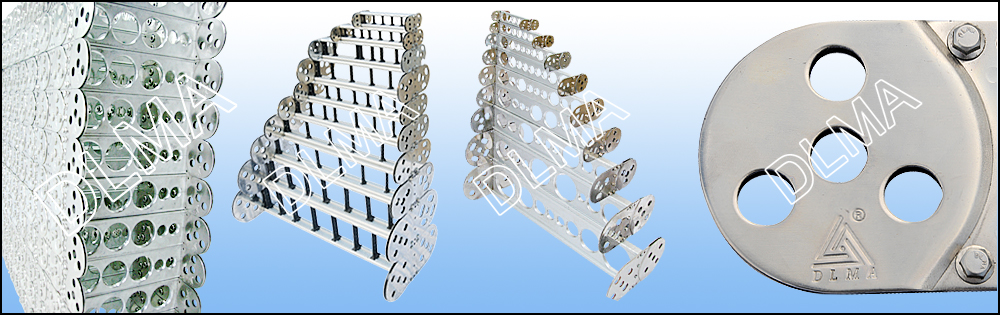

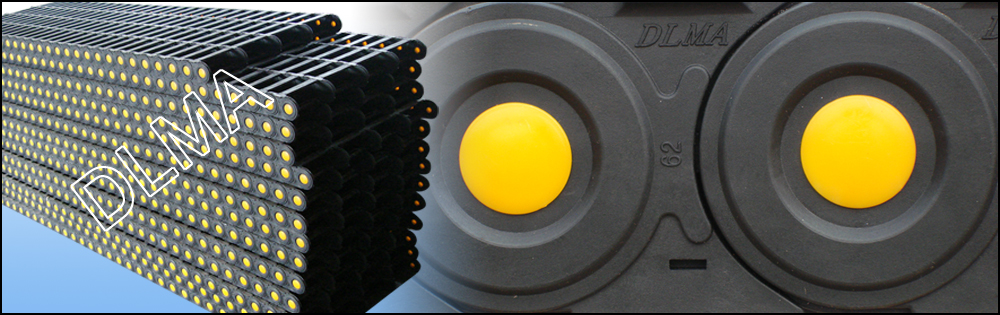

TL series drag chains are mainly consisting of chain plate ( top quality stainless steel with chromium plated ) , supporting board ( extruded aluminium alloy ) and pinshaft(alloy) , etc . There is no relative motions between the cables / rubber hoses and the drag chains , giving no deforming or twists. The chromium plated chain board has very nice -looking appearance and has very rational construction and flexible and high strength. It is reliable and easy to operate , install , dismantal or assemble . It is worthwhile mentioning that the anti - wearing performance has been improved greatly due to wear reslstant material and alloy pinshaff are used.The product is fexible to bending and has low resistance , giving low noises. it can be used for a very long period of time without any deformation or hanging down.The product is nice-looking , which makes the machine tool unit nicer Iooking as a whoIe and makes the machine tools and machineries more competitive in the international market.

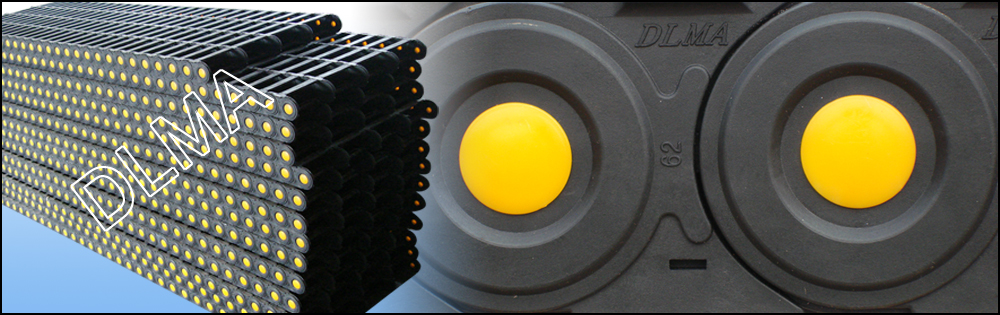

1.The drag chain can adapt to max.moving speed of 40m / sec .

2.When at the max moving speed , the sound pressure of noises shall not be greater than 68 db.

3.The Service life of the drag chain shaIl not be Iess than 1 million times ( reciprocating ) .

|